The Working Principle of Air Shock Absorbers

Time:

Air shock absorbers (pneumatic shock absorbers) are key in vehicle suspensions and industrial machinery. Unlike hydraulic types relying on oil, they use compressed air to absorb vibrations, reduce impacts, and maintain stability—leveraging air compressibility and component coordination.

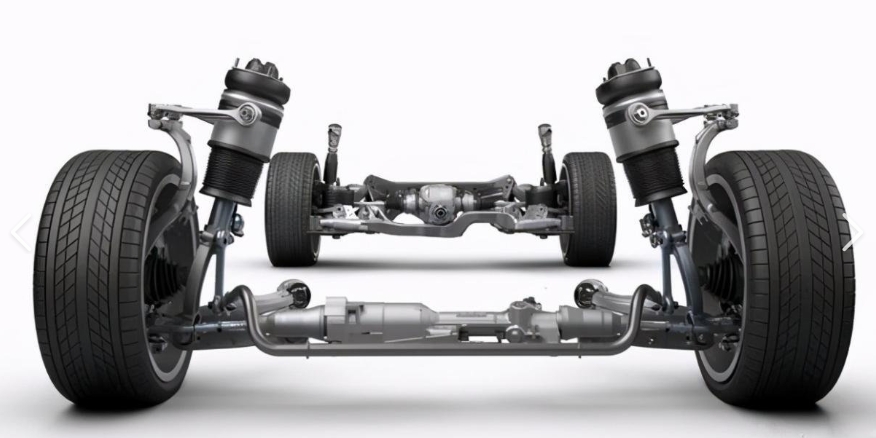

1. Core Components

A typical air shock absorber has 5 key parts:

- Air Spring (Air Chamber): Sealed, flexible container (reinforced rubber/composite) storing compressed air; acts as the main "cushion" for impacts.

- Compressor: Electric/mechanical device that pumps air into the air spring to adjust pressure for load changes.

- Pressure Sensor: Monitors real-time air pressure and sends data to the control unit.

- Control Unit (ECU/MCU): Processes sensor signals and commands the compressor/exhaust valve to adjust pressure.

- Damping Valve: Controls air (or auxiliary oil) flow; regulates air spring compression/rebound speed to avoid excessive bouncing.

2. Basic Working Process

Operation follows a cyclic compression → pressure adjustment → rebound sequence, adapting to external forces:

Step 1: Compression from Impact

When a vehicle hits a bump or machinery takes sudden load, the wheel/base pushes up on the absorber, compressing the air spring:

- Air chamber volume decreases; air pressure rises rapidly (per Boyle’s Law).

- Compressed air absorbs most impact energy, preventing transfer to the body/frame.

Step 2: Pressure Adjustment

The pressure sensor detects changes and signals the control unit, which adjusts in real time:

- Higher load: Compressor adds air to raise pressure (maintains ride height, avoids sagging).

- Lower load/flat road: Exhaust valve releases excess air to lower pressure to optimal level.

Step 3: Rebound

After impact, compressed air expands the air spring to restore the absorber’s original length. The damping valve restricts air flow to slow expansion—eliminating repeated bouncing for smoothness.

3. Performance-Enhancing Mechanisms

A. Adaptive Damping

Modern absorbers have ECU-controlled adjustable damping valves:

- Rough roads: Valve opens wider (faster air flow = softer ride, more vibration absorption).

High speed/sharp turns: Valve narrows (restricted air flow = stiffer suspension, better handling, less body roll).

Conteteco Air Suspension System - Your premier choice for safer, worry-free riding.